Product Specification

| Product Key Word | Customized Hardware Fixture/Jig for Hardware products,electronic cigarette, mobile phones, metal shell products fixture,etc. |

| Material | Metal:Stainless steel,and OEM according to your request |

| Surface treatment | Anodicoxidation treatment , Laser marking & Silk screen, Printing, Harden etc.Accept customized |

| Flatness Tolerance | ±0.01mm |

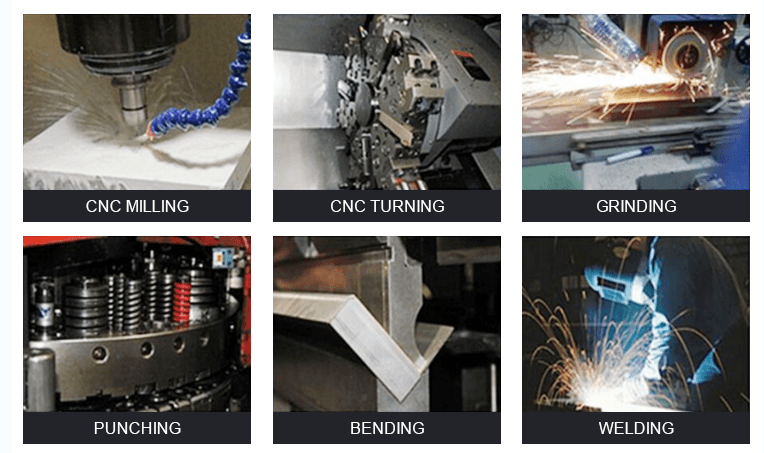

| Process | CNC machining, Turning, Milling, Grinding, Tapping, Drilling etc. |

| Certificate | ISO9001:2015, TUV, ROHS |

Production Processes

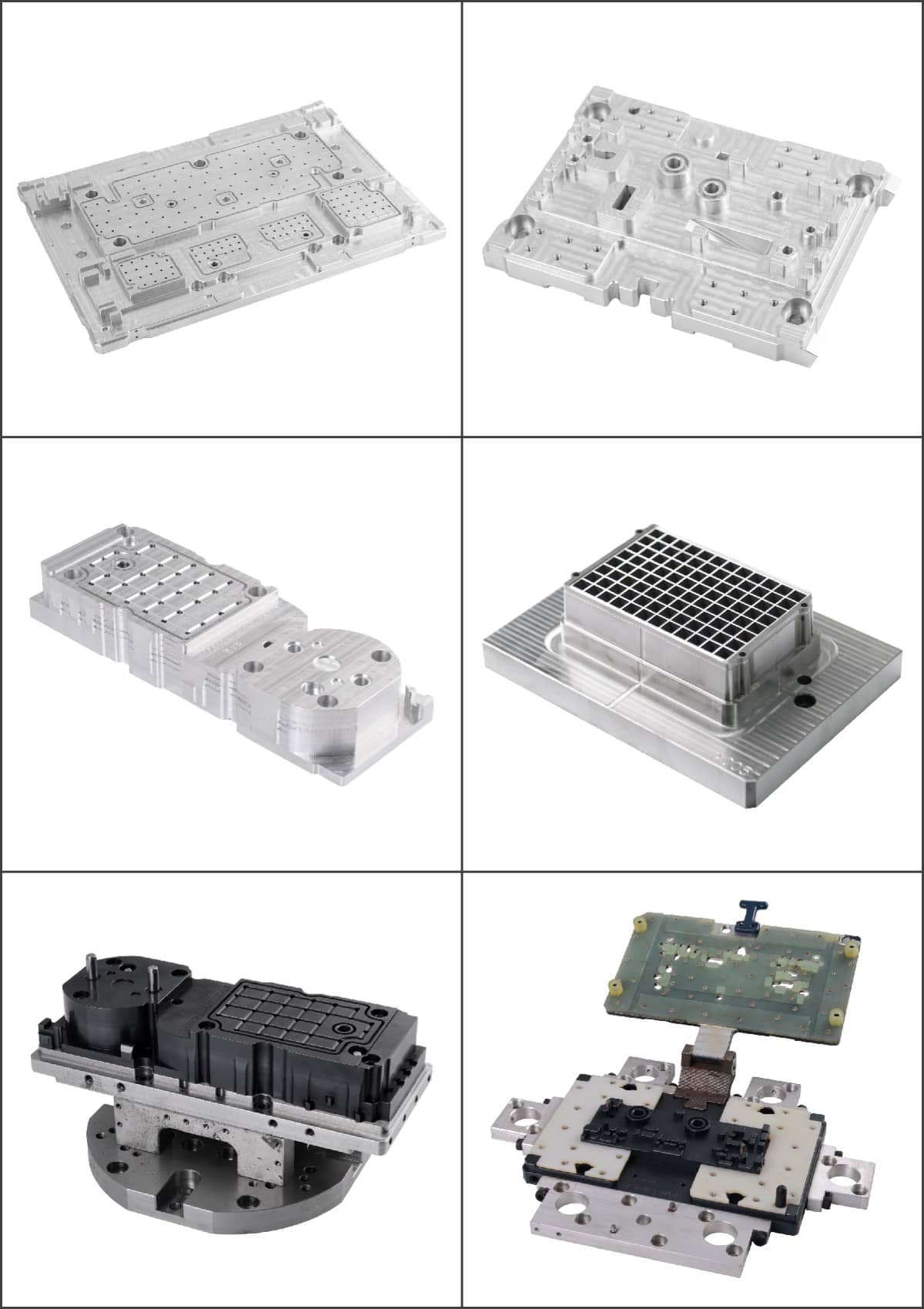

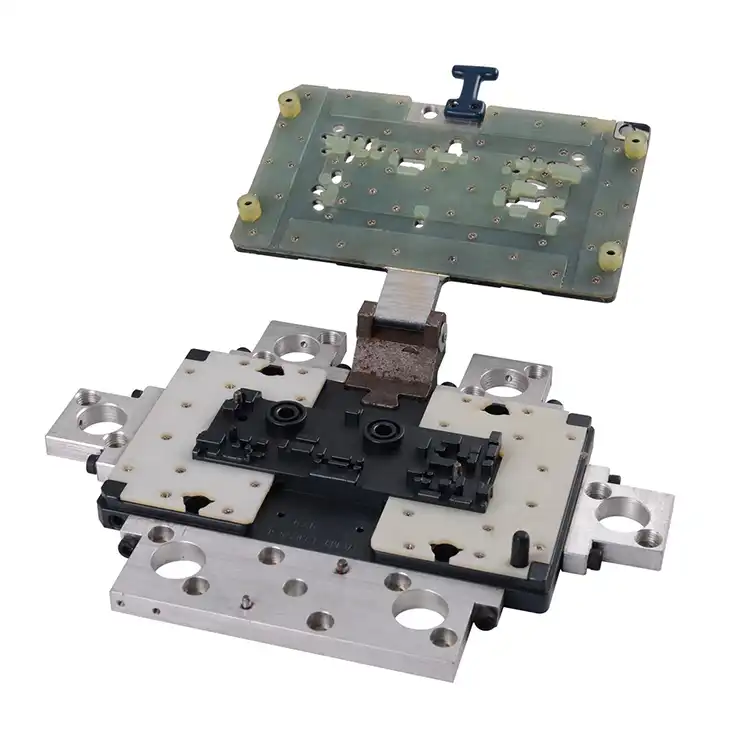

Product Display

Workshop

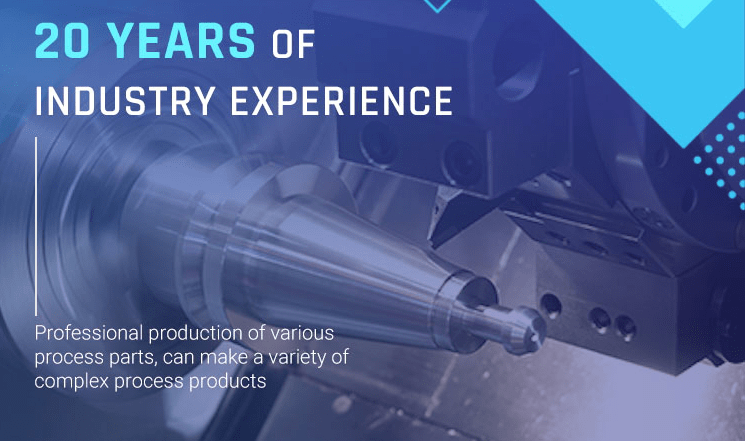

Advantage

> Technological Innovation -- Complicated curved surfaces and functional structure prototypes can be quickly formed.

> Processing Speed -- Short production cycle, fast delivery, ensure delivery in accordance with the agreed delivery date.

> Product Quality -- Good quality, guaranteed material accuracy up to 0.01mm to 0.05mm.

> Highly Confidential -- Multiple confidentiality measures protect customer information, more assured.

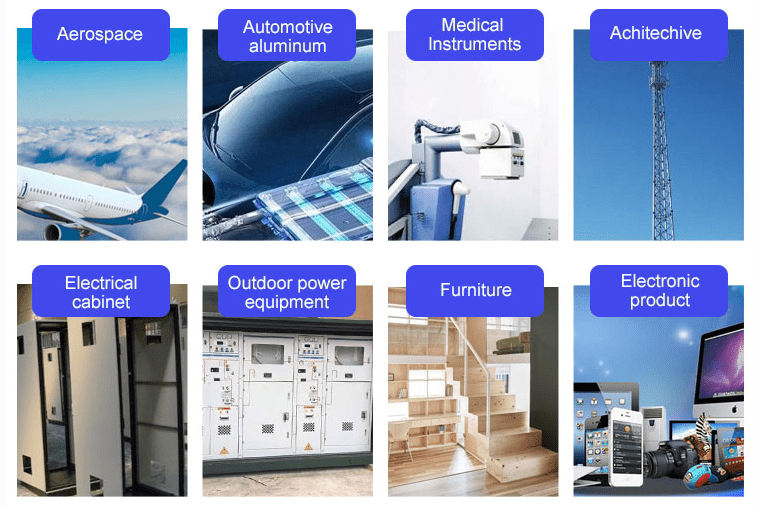

Aplication

Delivery ,Transportation and Service

About shipping

For the samples & prove samples we usually use by air transportation : which include DHL, FEDEX, UPS, EMS, TNT ; And for bulk order products we propose use by sea ,train and road transportation,which are the economy shipping term for buyer choosing. Therefore, you can provide us with your courier account and your shipping logistics agent to shipment the goods, or we will help you choose the cheapest shipping term for your confirmation.

FAQ

Q1.Are you a manufacturer or a trading company?

We are a 5000-square-meter factory located in Dongguan city, Guangdong province,China.

Q2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, technical data, quantity and surface treatment information.

Q3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for provide to accurate quotation.

Q4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

Q5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

Q6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

Q7. How do you control the quality?

(1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

Q8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will offer the analyse report and find the solution for you asap.

Q9. What services can we provide?

Delivery Terms: FOB,EXW;

Payment Currency:USD,EUR,CNY;

Payment Type: For samples accept transfer by T/T,Credit Card,PayPal,Western Union; For bulk products should be 30% deposit prepaid after confirmation orders, and the balance payment paid before shipment.

OEM Hardware Jig For Filter Treatment Machine Auto Parts Fixture Tooling Components

OEM Hardware Jig For Filter Treatment Machine Auto Parts Fixture Tooling Components

Customized Keyboard Treatment Jig Auto Parts Fixture Tooling Components

Customized Keyboard Treatment Jig Auto Parts Fixture Tooling Components

Fabrication Cellphone Tray Parts Jig Auto Parts Fixture Tooling Components

Fabrication Cellphone Tray Parts Jig Auto Parts Fixture Tooling Components

Fabrication Cellphone Tray Parts Jig CNC Milling Machining Custom Metal Fixture

Fabrication Cellphone Tray Parts Jig CNC Milling Machining Custom Metal Fixture

Fabrication Cellphone Tray Parts Jig CNC Machined Auto Parts Fixture

Fabrication Cellphone Tray Parts Jig CNC Machined Auto Parts Fixture

Precision Fabrication Spare Parts Fixture CNC Machining Auto Parts Jig

Precision Fabrication Spare Parts Fixture CNC Machining Auto Parts Jig

Precision Injection Mold Casting Fixture CNC Machining Auto Parts Jig

Precision Injection Mold Casting Fixture CNC Machining Auto Parts Jig

Precision Injection Mold Die Casting Fixture CNC Machining Auto Hardware Parts Jig

Precision Injection Mold Die Casting Fixture CNC Machining Auto Hardware Parts Jig

Non Standard Automated Parts Fixture Tooling Components High Precision Hardware Jig

Non Standard Automated Parts Fixture Tooling Components High Precision Hardware Jig